Increased safety when operating with hydrogen

The Hydrogen Leak Detector (HLD) provides early, reliable and accurate hydrogen readings, allowing industries to enhance operational safety, minimize risks, and comply with stringent safety regulations.

Backgrouond

Hydrogen is a key enabler of the clean energy transition, offering a high energy density and zero emissions when used in fuel cells. However, its unique properties, such as high flammability and rapid diffusion, present significant safety challenges. The ability to detect hydrogen leaks at an early stage is crucial for preventing hazardous situations, including fires and explosions, ensuring safe and reliable hydrogen adoption across various industries.

Importance of Early Hydrogen Leak Detection

Hydrogen’s small molecular size enables it to escape through seals, joints, and micro-cracks in storage and transport systems. Due to its low ignition energy and nearly invisible flames, detecting leaks before they reach dangerous concentrations is essential. Traditional detection methods are often inadequate in identifying low-level leaks, making advanced detection technology a necessity.

The HLD Series is designed to detect hydrogen at trace levels, providing early warning signals to prevent hazardous accumulations. Operators can significantly enhance safety and operational efficiency by integrating this technology into hydrogen storage, fuel cell applications, and industrial processes.

Key benefits of the Hydrogen Leak Detector (HLD)

- high sensitivity & Accuracy:

detects very small hydrogen leaks before they pose a safety risk. - rapid response time:

fast leak detection enables quick corrective actions, preventing escalation. - reliability & durability:

designed for industrial environments with robust sensor technology. - regulatory compliance:

supports adherence to hydrogen safety standards and industry regulations. - cost savings & efficiency:

reduces downtime, prevents accidents, and lowers maintenance costs.

HLD applications across industries

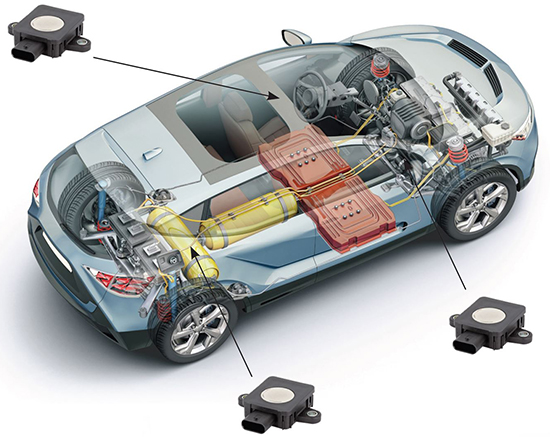

Fuel Cell Electric Vehicles (FCEVs)

Fuel Cell Electric Vehicles (FCEVs) depend on hydrogen as a clean energy source. Any hydrogen leakage in the fuel system can pose safety risks and reduce vehicle efficiency. The Hydrogen Leak Detector provides continuous monitoring of FCEV hydrogen tanks, pipelines, and fuel cell stacks, ensuring early detection of leaks and maintaining safe operation. By detecting leaks early, the Hydrogen Leak Detector helps prevent dangerous situations and enable hydrogen fuel efficiency.

Hydrogen Fueling Stations & Transportation

Hydrogen-powered vehicles rely on high-pressure storage tanks and refueling stations, where leaks can lead to serious safety hazards. The Honeywell Hydrogen Leak Detector ensures continuous monitoring of fueling infrastructure to detect leaks promptly, preventing potential ignition and ensuring compliance with safety protocols. Additionally, integrating HLD technology into hydrogen dispensers and storage systems enhances operational efficiency, minimizes downtime, and builds consumer confidence in hydrogen fueling infrastructure. The HLD Series ensures continuous monitoring of fueling infrastructure to detect leaks promptly, preventing potential ignition and ensuring compliance with safety protocols.

Hydrogen Generators

Hydrogen generators are essential for on-site hydrogen production in industrial, medical, and energy applications. Ensuring leak-free operation is critical to maintaining efficiency and safety. The HLD sensor continuously monitors hydrogen generators, detecting leaks at the earliest stages to prevent hazards such as gas buildup, fire, or explosion. By integrating HLD technology, operators can enhance safety, optimize system performance, and comply with stringent safety regulations.

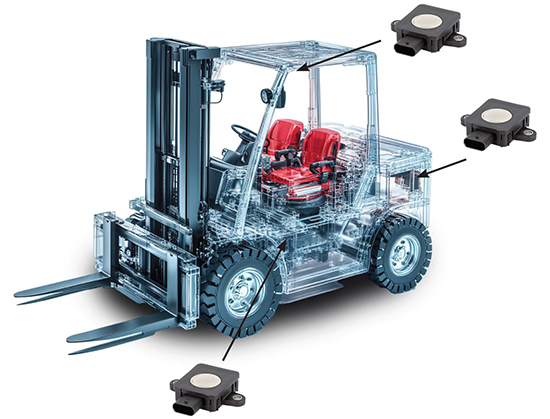

Industrial Hydrogen Applications

Industries such as chemical processing, metal refining, semiconductor manufacturing, and warehouse logistics rely on hydrogen for various operations. Hydrogen fuel cell forklifts are increasingly used in warehouses, logistics centers, and manufacturing facilities due to their fast refueling capabilities and zero emissions. However, hydrogen leaks in industrial settings and confined environments can pose significant safety risks.

The presence of undetected leaks can lead to hazardous conditions, production losses, and regulatory non-compliance. The HLD Series ensures real-time monitoring of hydrogen distribution systems and forklift fueling stations, reducing risks and improving workplace safety. By adopting HLD, industrial operators can protect personnel, maintain operational efficiency, and prevent costly downtime, while also ensuring the safe operation of hydrogen-powered forklifts in high-traffic environments.

Hydrogen Storage & Distribution

Hydrogen storage facilities and pipeline networks must prevent leaks to maintain system integrity and avoid energy losses. HLD high-precision sensors enable early detection, allowing for immediate corrective action and maintaining a secure hydrogen supply chain. With its ability to detect even minute hydrogen leaks, the HLD Series improves system reliability, reduces maintenance costs, and ensures the long-term sustainability of hydrogen distribution networks.

Hydrogen storage facilities and pipeline networks must prevent leaks to maintain system integrity and avoid energy losses. The HLD high-precision sensors enable early detection, allowing for immediate corrective action and maintaining a secure hydrogen supply chain.

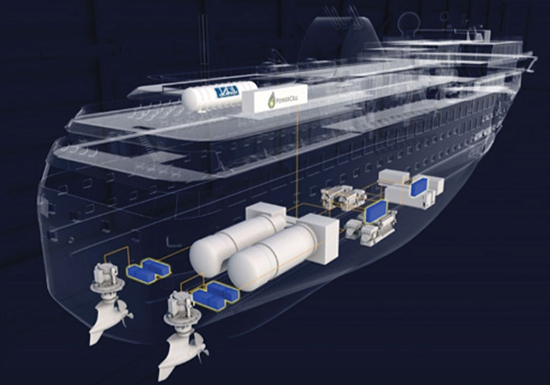

Marine Applications

The maritime industry is increasingly adopting hydrogen as a sustainable fuel alternative to reduce carbon emissions. Hydrogen-powered ships, submarines, and other marine vessels require advanced leak detection systems to ensure safety at sea. The HLD Series provides early detection of hydrogen leaks in marine fuel systems, preventing risks such as fires or explosions in confined ship environments. By integrating HLD, marine operators can enhance vessel reliability, protect crew members, and support global efforts to transition to cleaner maritime energy solutions.

More information

Products

Contact person

André Schärer

+41 61 264 10 28

a.schaerer@sibalco.ch