Honeywell PCB pressure sensors for many applications

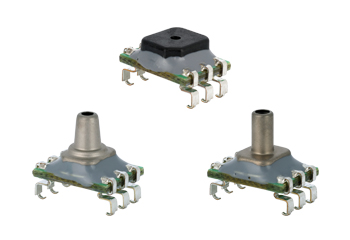

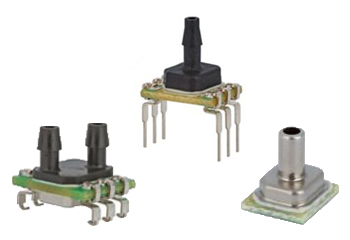

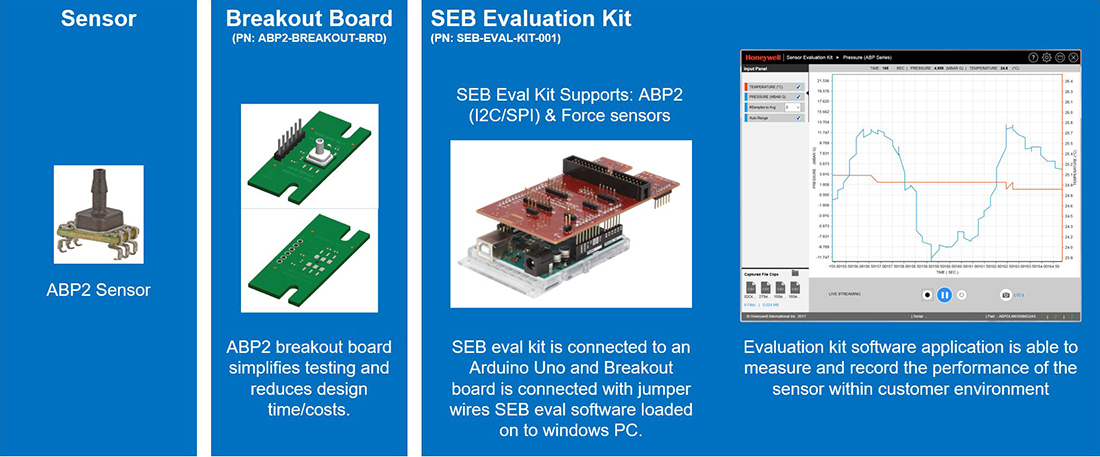

The ABP2 series comprises a highly configurable, versatile and cost-effective pressure sensor for PCB mounting. With its high accuracy, excellent long-term stability, small design, low power consumption and extensive media compatibility, the ABP2 is ideal for a wide range of medical and non-medical applications.

Furthermore, unlike other suppliers, the ABP2 offers compatibility with a wide range of liquid media on both connections.

Key features

- large pressure range

2.5 mbar to 20 bar | 0.25 kPa to 2 MPa | 0.04 psi to 290 psi high burst pressure - low overall error tolerance

up to ±1.5% FSS - high long-term stability

±0.25% FSS BFSL - operating temperature range

-40 to110°C - calibration range

-40 to 110°C - digital output

I2C, SPI - IoT (Internet of Things)

capable interface - temperature output

available - media compatibility long-term

compatibility with a wide range of liquid media - power consumption

extremely low power consumption (up to 0.01 mW typical average power, 1 Hz measurement frequency) - complies with IPC/JEDEC J-STD-020E moisture sensitivity level 1

- suitable for food

- NSF-169-, LFGB- and BPA-compliant materials

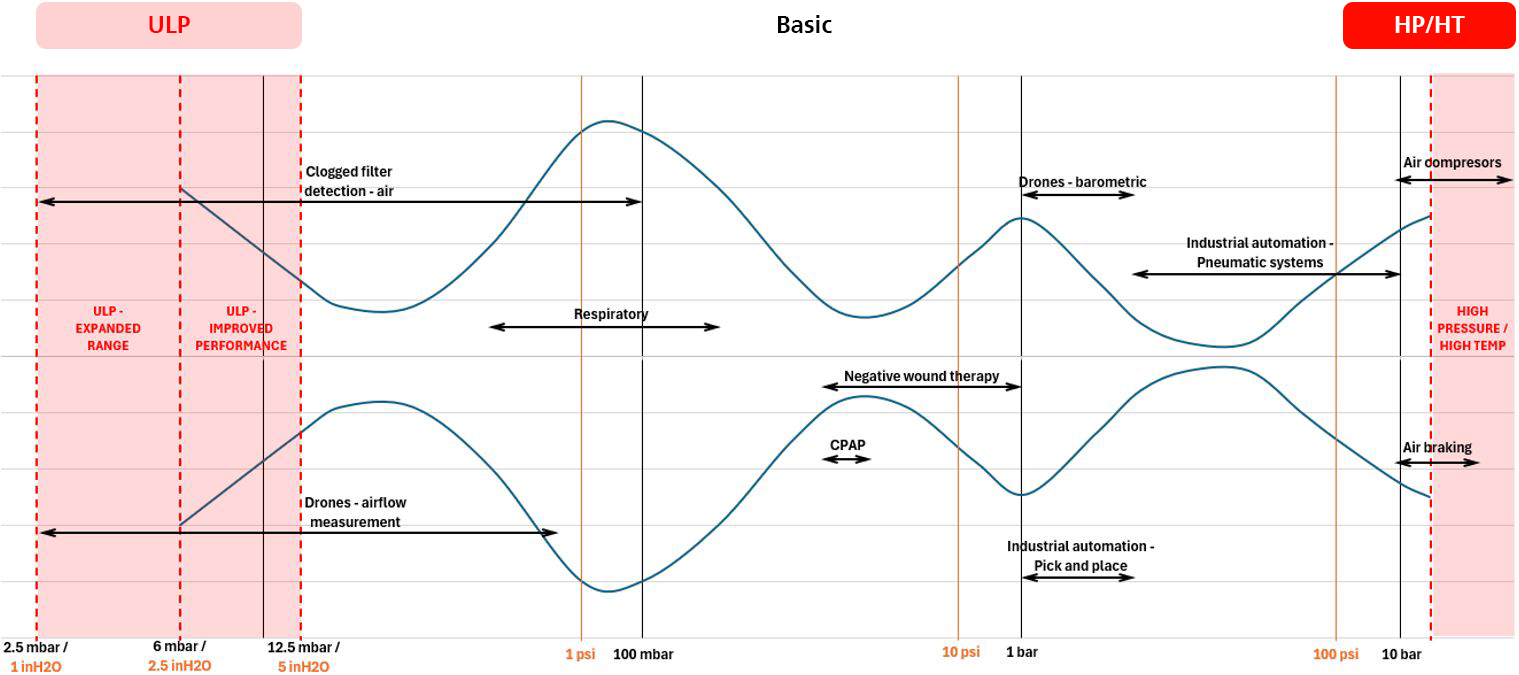

ABP2 – Series categories

The ABP2 series is divided into 3 categories

| ULP | (ultra low pressure) | +-2.5 mbar – 12.5 mbar |

| Basic | (basic variants) | 10 mbar – 12 bar |

| HP/HT | (high pressure / high temperature) | 12 bar – 20 bar |

The specification features, available housings and connection options vary depending on the category. Details can be found in the relevant data sheets.

Customer benefits

- easy integration:

The small size saves space on the printed circuit board (PCB) and makes installation easier in small devices. Meets IPC/JEDEC J-STD-020E moisture sensitivity requirements Level 1:

- Enables the avoidance of thermal and mechanical damage during reflow assembly due to reflow soldering and/or repairs that can occur with lower-performance sensors.

- Enables unlimited shelf life when stored below 30 °C/85 %RH (simplifying storage and reducing scrap).

- Eliminates lengthy burn-in processes prior to soldering.

- Enables lean manufacturing through stability and usability shortly after soldering. - cost-effective:

The small size allows developers to reduce design and manufacturing costs while ensuring improved performance and reliability of the systems they design. - exactly:

Total error budget (TEB) and extended pressure range enable system performance to be optimised by improving resolution and system accuracy. - flexibility:

Supply voltage range, a variety of pressure units, designs and ranges, output options and a wide operating temperature range simplify application-specific use. - flexible use:

Its compatibility with wet media, low power consumption and temperature output options make the sensor a versatile choice for Internet of Things applications.

Differentiating features

- the application-specific design ensures suitability for a wide range of customer requirements.

- the digital output allows the sensor to be integrated directly into the customer's circuit without requiring major design changes.

- long-term media compatibility ensures safe and sustainable use with liquid media.

- total error tolerance / low drift:

- provides a more comprehensive measurement of performance across the compensated temperature range, minimising the testing and calibration of each sensor and thereby potentially reducing manufacturing costs: improves sensor accuracy and offers easy sensor interchangeability due to minimal variation from part to part.

- improves sensor accuracy.

- offers easy interchangeability of sensors due to minimal variations from part to part.

Possible applications

- medical technology:

ventilators/portable ventilators, CPAP, blood analysis, blood pressure monitoring, breast pumps, medication dosing, hospital beds, massage devices, oxygen concentrators, patient monitoring, sleep apnoea devices, urine analysis devices and wound therapy - industrial applications:

HVAC transmitters, life sciences, materials handling, pneumatic control and regulation, process gas monitoring and valve positioning/positioners - household products:

air beds, coffee machines, washing machines, level gauges, dishwashers, vacuum cleaners, hand dryers and rice cookers - transport:

Compressed air brakes, CNG monitoring, forklift trucks and fuel level measurement

Contact / support / sample order

If you have any further questions about the product, require technical support, would like to order samples or have any other queries, please do not hesitate to contact us. We look forward to hearing from you!

More information

Products

Contact person

André Schärer

+41 61 264 10 28

a.schaerer@sibalco.ch