What Plating Option Is Best For My Connector?

Gold, tin or selective plating

Author: Danny Boesing @Samtec

Choosing the right plating is critical to the success of a connector system. Plating affects the connector’s performance, life cycle, quality, and cost. Let’s begin with cost. A recent blog explains that the major costs in a connector are the plastic body, the pins, plating on the pins, the labor to assemble it, and the packaging. And with most connectors, the bigger ticket items are the pins and the plating.

Choosing the right plating is critical to the success of a connector system. Plating affects the connector’s performance, life cycle, quality, and cost. Let’s begin with cost. A recent blog explains that the major costs in a connector are the plastic body, the pins, plating on the pins, the labor to assemble it, and the packaging. And with most connectors, the bigger ticket items are the pins and the plating.

For example, on a micro pitch, high density interconnect product, the pin and plating may account for about 25% – 30% of the total cost of the connector. But on a basic 2.54 mm centerline terminal strip (“header’), it can account for up to 60 – 70% of the total cost of the connector.

That’s because the relative size of the plastic body on a miniature, mold-to-position microminiature connector is almost always larger than the body on a basic cut-to-position strip-line connector. And, of course, the pins are going to cost more if you’re using gold plating.

As I mentioned in that previous blog, I can’t speak for all connector companies when it comes to costs. The majority of examples I’m using here relate to Samtec interconnects, but I bet the principles apply to other connector companies as well.

What do we recommend?

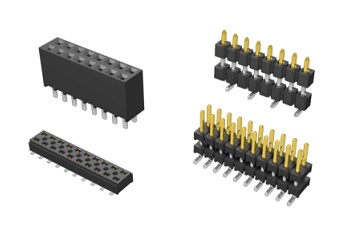

Designers frequently ask what plating finish we recommend. There are numerous considerations to take into account (as evidenced by the variety of plating options like the TSW series on most basic connectors), but the best plating finish is whatever meets your system requirements, at the lowest cost. In other words, make sure it works and meets your quality design specifications, but don’t over-design on the plating.

Gold Plating

Gold is generally specified for high reliability, low voltage, or low current applications. Gold is used in high cycle applications because it’s rugged and has excellent wear properties (here’s example of a high-cycle connector the SFM series). Our gold is alloyed with cobalt, which increases the hardness. We also recommend gold for hostile environments, because it will remain free of oxides which could cause an increase in contact resistance. Gold is a noble metal, which means it doesn’t react much to its environment.

Tin Plating

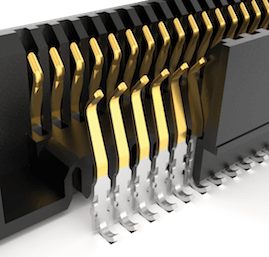

Tin is a lower cost alternative than gold, and has excellent solderability. Unlike gold, tin is not a noble metal. Tin plating starts to oxidize the moment it’s exposed to air. So a tin plated contact system requires greater normal forces and a longer contact wipe area to break through this oxide film. Check out the brief video below.

The bottom line is, tin is better for applications with fewer cycles because of the extra forces exerted on the contact, and simply because it’s a softer metal. (The connector in the video above is the SSW series).

Normal Force

The distinction between gold and tin comes down to normal force. Gold requires a much lower amount of normal force compared to tin. Fine pitch connectors do not have the space for a relatively large, thick contact beam with high deflection; this is needed to generate the normal force tin required in tin-plated contacts.

Therefore, due to physical size constraints of microminiature connectors, gold is often the only choice available. In other words, we would use tin if we could. Tin is used in the connector contact area where the proper normal force can be generated, and it is used in benign environments. Tin will oxidize, and therefore a higher amount of normal force and contact wipe is needed to break through the inherent layer of oxidation. Again, check out the video above.

Selective Gold + Tin Plating Option

Selective gold-tin plating is Samtec’s most popular plating option because it provides designers with the best of both worlds. The contact area, the critical area where the contact interfaces the terminal pin and the signal is transferred, has the reliability of gold. The tail, which is soldered to the board, has the lower cost and solderability of tin.

Tin-Lead, Gold-Flashed Palladium Nickel

Of course other plating options are available for specific applications. Two common examples include tin-lead plating and gold-flash palladium nickel. Tin-lead is used in military applications, and benefits include a low eutectic temperature, and the presence of lead inhibits the formation of tin whiskers. Gold-flashed palladium nickel is used for extremely high cycle applications. But, for most typical applications, gold, tin, or selective plating will work just fine.

Quick Summary

Gold for high reliability, high cycle, low voltage applications.

Tin is used for applications with fewer cycles, it’s less expensive, and it holds solder.

Selective plating, with gold in the contact mating area and tin on the tail, is usually the best option.

The products in our Webshop