Good news about board stacking connector solutions from Samtec

Author: Danny Boesing @Samtec

“The good news is, Samtec has more ways to stack two or more PC boards than anybody else in the connector industry,” I told a Designer when asked about our two-piece, pin-and-socket board stacking connector sets.

Usually, the “bad news” follows the “good news.” But the second sentence was, “The good news is, Samtec has the industry’s best online tool to select the best board stacking connector set for your application. Not just one product series, but the complete part numbers to the mated connector sets.”

I’m referring to our new Solutionator® Flex Stacking tool, an online connector search tool that provides you the mated connector set that meets your connector board stacking design requirements. That’s worth repeating: the tool gives complete part numbers of the two mating connectors that meet your design specifications.

Almost every other connector search on the planet leads you to one connector, and then you still have to search to find the other half of the mated set. In other words, you have to do at least two searches. And, after these two searches, you still have to figure out the stack height of the mating connector system. And that can be, putting it mildly, a major hassle. With the Solutionator tool, you can literally locate the optimal mated connector set for your board stacking application in a matter of seconds.

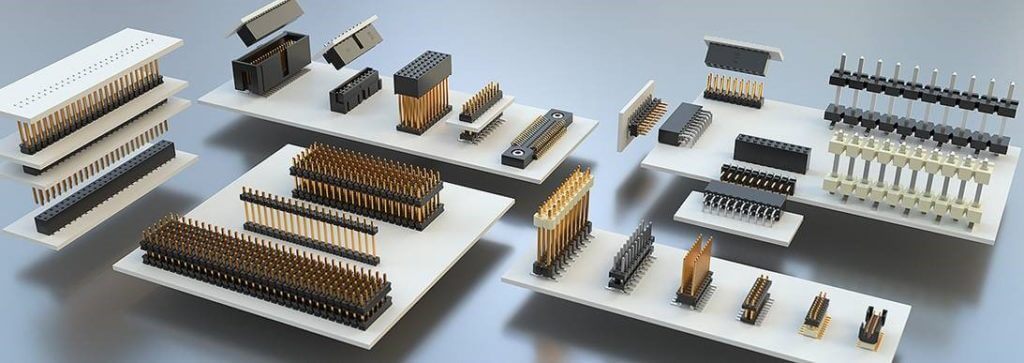

These connector sets are used in all types of industries, including industrial, robotics, computers and peripherals, telecom, data comm, medical, test and measurement, instrumentation, mil/aero, transportation, automotive, and consumer, just to name a few.

Flex Stacking Connector Solutions

Flex Stacking Connector Solutions

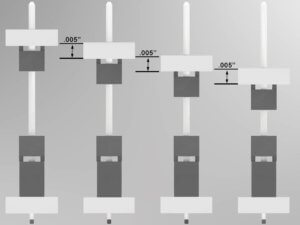

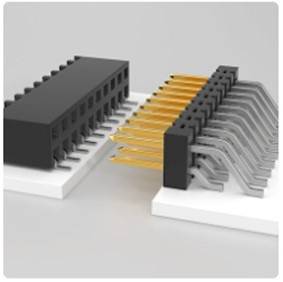

Samtec has more ways to connect two or more boards than any other interconnect provider. One really cool (and unique) capability is what we call “Flex Stack.” Flex Stack is the ability to move the plastic insulator (body) up and down the terminal pin in increments of 0.005″ (0.127mm) on header strips and dual-body stackers. If you need a .360″ stack height, we’ve got it. Ditto 0.365”, 0.370”, 0.375” and so on. Designers can create standard part numbers for very precise, non-industry-standard-board stacking heights.

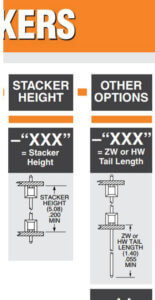

You specify the post height and or stacking height — the distance between the two plastic bodies — in the standard Samtec part number. See the “-XXX” to the right.

You specify the post height and or stacking height — the distance between the two plastic bodies — in the standard Samtec part number. See the “-XXX” to the right.

This allows designers to order a custom stack height connector system with:

- a standard part number

- no minimum order size

- no long lead times

- and no tooling or NRE charges

The Flex Stacking capability is available on stackers and terminal strips on a variety of pitches from 0.200″ (5.08mm) to 0.80mm.

Fine pitch for micro, to big spacing for power

Samtec board stacking connector systems are in a variety of centerlines, or pitches, including 2.54mm (0.100″), 2.00mm, 1.27mm (0.050″), 1.00mm and 0.80mm. There’s also power-to-board systems on 5.08mm (0.200″) and 3.96mm (0.156″) pitches.

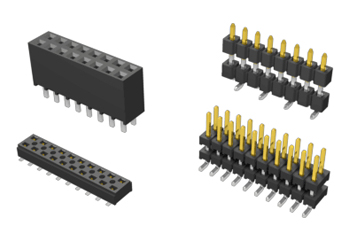

Header and socket systems are available in a variety of contact styles, for different applications, from rugged to the easy life. Samtec contact systems include:

- Tiger Eye: for high-cycle, rugged, high shock and vibration applications

- Tiger Buy: an economical solution for rugged, high-impact applications

- Tiger Claw: for low profile board stacking, and when the terminal pin needs to pass through the socket strip

- Tiger Beam: a single beam design for basic connections that will not face much adversity

- Edge Rate: a high-speed contact system

Low profile to elevated, and all points in between

Board stacking connector systems are available in all stack heights, from 3.5 mm to 48 mm. Our most popular stack heights are from .250″ to .750″ between boards. But there’s tremendous demand for low-profile designs for handheld and miniature products, or any place where space is tight.

Although we usually think of electronics as continually shrinking in size, many designers actually require extra space between boards. They may have tall components on one board, or maybe they need to have extra clearance to gain access to a board, or maybe they need space for airflow and cooling. Whatever the reason, Samtec has connector sets that are tall, and stable, for elevated board stacking.

Stacking connector orientation

Stacking connector orientation

All of these board stacking connector systems are available in:

- parallel (also called "vertical" or "sandwich") orientations

- right angle designs (also called "perpendicular" or "90°")

- and in horizontal (or "coplanar" or "180°")

Almost any size connector

The plastic insulators, or bodies, on most of these two-piece, pin-and-socket connector systems are full strip, cut-to-position designs. For example, the terminal strip for a 2.54mm pitch basic terminal strip (a “header”) is a 50-position strip. That means you can order anywhere from a one-position connector to 50 pins, and they are all standard part numbers with no minimum order sizes.

Likewise, they’re all available in dual-row designs, so you can get anywhere from a two-position header (maybe for a shunt?) to 100 pins, and all sizes in between. Well, as long as the size is divisible by two.

If you want to peruse through the entire product line, here’s link to stacking connectors.

Or, make it easy on yourself, use the Flex Stacking Solutionator tool.