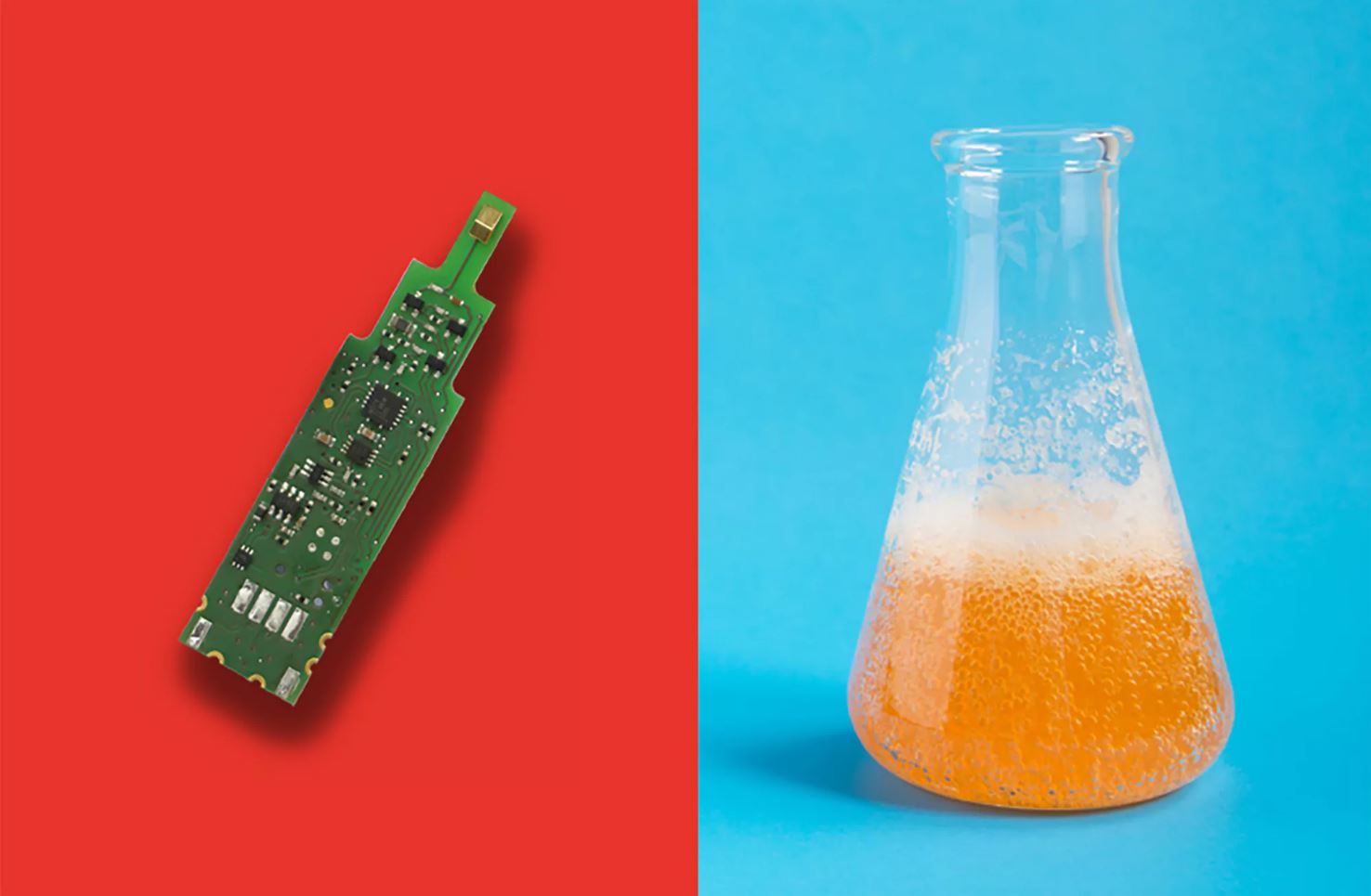

Quality sensors for innovative detection of fluid properties (EBE)

EBE's QCRB quality sensors open up ground-breaking possibilities for measuring fluid properties in OEM and process applications. These innovative sensors combine capacitive and conductive measurements for precise media detection and enable comprehensive monitoring of fluid properties. Many OEM and process applications require the detection and monitoring of fluid properties.

Quality deterioration over time

- Oxidation of lubricants

- Contamination with foreign substances

Concentration measurement

- Preventing an overdose

Air/gas bubble detection

- Recognising foam formation

- Prevention of air bubbles in hoses

- Idle detection

- Detection of separating layers

Determination of medium

- Prevent damage from foreign substances

Quality sensors from EBE offer a way to achieve all this with just one sensor. Applicable for gases, liquids, solids and highly viscous media, the sensors can be accommodated in hygienic, robust housings and detect the media properties without direct contact with the medium.

They enable the simultaneous acquisition of capacitive and conductive measured values in real time, which previously required the use of two or more measuring devices. They cover the detection of media in a range of relative permittivity (εr) from vacuum to water and beyond.

Capacitive measuring ranges

0,1pF up to 80pF

Conductivity

typ. 0,1 up to 200mS/cm

The sensors offer real-time calibration to compensate for environmental influences, ensuring high stability over time and repeatability. They are ideal for mass production and enable OEMs to offer high-quality quality analyses cost-effectively.

Especially in sectors such as the food and beverage industry, pharmaceuticals and medical technology, where strict regulations apply, sensor technology provides valuable real-time data.

Cost reduction

- Reduction of laboratory tests

- Assurance of product quality

- Automatic traceability

Increasing production efficiency

- Predictive maintenance

- Reduction of production downtimes

- Optimisation of maintenance cycles

For further information, please contact us by e-mail.

E-mail enquiry about the product