Common mistakes when crimping Micro-Connectors

Micro-Connectors crimping

Author: Wendy Jane Preston @Harwin

Micro-connectors have an important role to play in demanding environments, and every part of the assembly must be the best quality possible. By specifying a quality product, you are making sure the manufacturer is doing their bit in making your system secure. However, if you are going to crimp and assemble connectors to wires in-house, your own systems need to reflect the same level of quality.

As the saying goes, “Fail to Prepare, Prepare to Fail” – if you don’t get all your planning and preparation in place then you may fail to meet the quality level required to make these connectors perform as they were designed. Here is a list of common mistakes that can be avoided with planning and preparation – always check the manufacturer’s recommendations!

At the Design Phase:

- The wrong cable type has been specified – not the same type as the manufacturer recommends. Additional testing will need to be completed before the design is fixed, to confirm if the connector can accommodate it and function as specified.

- The cable size specified is too big – either the conductor or the insulation is not going to fit into the crimp contact.

- The stranding is not correct – has the manufacturer recommended stranded or solid core wires? If you do need to use a specific type for a good reason, again carry out testing to confirm suitability before the design is fixed.

At the Preparation phase:

At the Preparation phase:

- Assumptions are made about the crimping method based on other products – the full manufacturer’s instructions and recommendations have not been obtained, and there may even be training videos.

- Notes have not been made in the manufacturing documentation about specific peculiarities to the specific connectors – are you sure that’s an inspection hole and not a plating hole?

- The wrong tools are used – it’s always convenient and less expensive to use the tools you have already, but these may not be appropriate

- Adequate wire preparation is not available; stripped wires have uneven insulation ends, and strands are uneven and not laying neatly.

- Test rigs are not manufactured – continuity testing in production will become a slow manual task without any fixtures to assist.

At the Training/Pre-production phase:

No additional product has been purchased for training and practice, so when it comes to production, the line runs short of connectors.

- The staff expected to carry out the crimping and assembly have not been shown all the manufacturer’s information or videos, and assemble the product badly. Damage occurs, and the product must be replaced.

At the Production phase:

At the Production phase:

- Contamination from the workplace gets into the product. Make sure the working area is clean and free from dust and debris.

- Contamination from the user’s hands – oil from other machines, cleaning fluids, even skin cells can contaminate the contact and connector and impact performance. Gloves have not been provided if applicable.

- The wrong tools are used (again) – all tools are out on the workbench, increasing confusion and the risk of choosing the wrong device.

- Magnification devices have not been supplied – as the product is so small, inspection and assembly are affected.

As you can see this is quite a list of potential errors and issues, any one of which can cause the connectors to not perform to their specifications. Don’t be afraid to ask for the connector supplier’s help – here at Harwin we can offer training videos, remote support and even onsite support. In addition, Harwin are prepared to remove all these problems for you by manufacturing cable assemblies for our connectors, on demand.

Convert to Ready-Made:

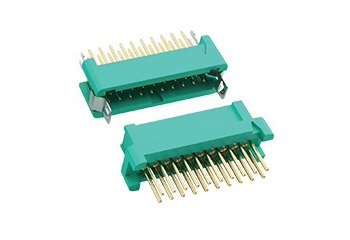

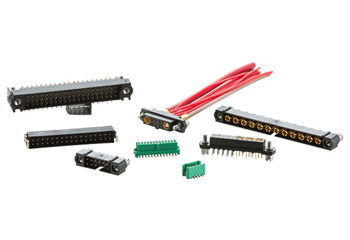

To save further time and resources, we recommend our readymade cable assemblies, available on the Gecko-SL range. At 1.25mm pitch, the contacts are so small that handling is tricky, and magnification is the only way to inspect. Gloves are definitely required to avoid skin cells from contaminating mating surfaces. The result is a very compact, high-reliability cable assembly suited for aviation, space, motorsport, defense or robotics industries – but the process to achieve these results can be difficult and costly for the inexperienced or unequipped.

To save further time and resources, we recommend our readymade cable assemblies, available on the Gecko-SL range. At 1.25mm pitch, the contacts are so small that handling is tricky, and magnification is the only way to inspect. Gloves are definitely required to avoid skin cells from contaminating mating surfaces. The result is a very compact, high-reliability cable assembly suited for aviation, space, motorsport, defense or robotics industries – but the process to achieve these results can be difficult and costly for the inexperienced or unequipped.

Harwin has designed, manufactured and stocked a wide range of cable assemblies: male and female single-ended or double-ended in all combinations; 26AWG PFTE insulated cable with 6, 12 or 18-inch (150, 300 or 450mm) lengths.

The cable assemblies are ready-made and in stock across the distributor network, fully inspected and tested by IPC-620 trained and experienced operators.

No hidden problems, no waiting, no extra costs.

![]() Cable Connectors and Assemblies

Cable Connectors and Assemblies

The products in our Webshop

High Reliability connectors