High-performance, high-quality medical connector systems

The medical electronics industry is one of the most important market segments for Samtec. Specific connector systems have therefore been developed for these applications and are used very successfully worldwide.

This blog presents various connector systems that are frequently used in medical electronics.

These are rugged, high-performance, high-bandwidth connector systems that meet the stringent quality, production, and compliance requirements of the medical industry. They also address the design challenges of signal integrity, power consumption, system optimization, and cost. Samtec connectors are used in imaging, medical equipment, surgical, point of care and monitoring, and therapeutics applications, among others.

Here is a quick overview of Samtec connector product families that are well-suited for the medical industry:

Micro rugged connector systems

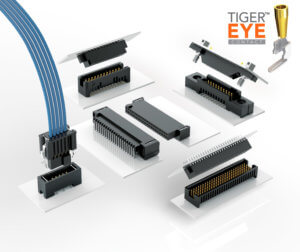

Designers don’t usually think of micro pitch connectors as being rugged, as being able to handle high mating cycles, or as having robust mechanical strength on the PCB, or with strong retention of mated connector sets. Samtec has a complete line of micro rugged products that can do all of the above. Our micro rugged products are just that — micro, and rugged. Here’s a quick overview of two of our leading micro rugged product lines:

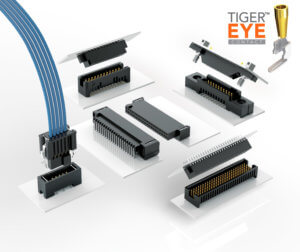

The Tiger Eye™ system is designed for high-reliability, high-cycle applications. Tiger Eye is available in board-to-board, discrete wire, and IDC cable systems, and in a variety of centerlines. Tiger Eye contacts are multi-finger, heat-treated, Beryllium Copper (BeCu) contacts designed for rugged environments. The superior spring properties of Beryllium Copper make it ideal for high mating cycle applications.

The Tiger Eye™ system is designed for high-reliability, high-cycle applications. Tiger Eye is available in board-to-board, discrete wire, and IDC cable systems, and in a variety of centerlines. Tiger Eye contacts are multi-finger, heat-treated, Beryllium Copper (BeCu) contacts designed for rugged environments. The superior spring properties of Beryllium Copper make it ideal for high mating cycle applications.

Samtec Edge Rate® interconnect systems are optimized for signal integrity performance (some are rated at 56 Gbps PAM4), feature increased contact wipe for reliability and durability, and are designed for higher cycle applications.

Edge Rate connectors are available in vertical, right angle, and edge mount terminations. They are available with all kinds of design options, like full 360 degree shielding, latching systems, guide posts, and differential pair configurations, to name a few.

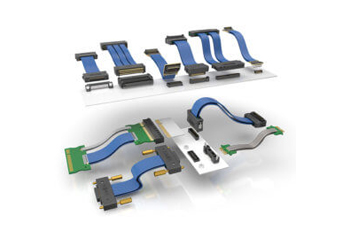

High-Speed Cable Assemblies

High-speed cable assemblies are most frequently used for medical imaging (MRIs, CT/CAT Scans, PET Scans, and Ultrasound) and rapid diagnostics. High-speed cable assemblies are available with micro coax and twinax cable for both single-ended and differential applications. Most designers incorporate a Samtec Flyover® cable system; this extends signal reach and density to achieve next generation speeds by routing signals through ultra-low skew cable instead of through a lossy PCB.

High-speed cable assemblies are most frequently used for medical imaging (MRIs, CT/CAT Scans, PET Scans, and Ultrasound) and rapid diagnostics. High-speed cable assemblies are available with micro coax and twinax cable for both single-ended and differential applications. Most designers incorporate a Samtec Flyover® cable system; this extends signal reach and density to achieve next generation speeds by routing signals through ultra-low skew cable instead of through a lossy PCB.

As bandwidth requirements increase, effectively managing heat and routing signals through lossy PCBs, vias and other components have become complex challenges. Samtec Flyover cable systems break the constraints of traditional signaling substrate and hardware offerings, resulting in a cost-effective, high-performance and heat efficient answer to the challenges of 112 Gbps bandwidths and beyond.

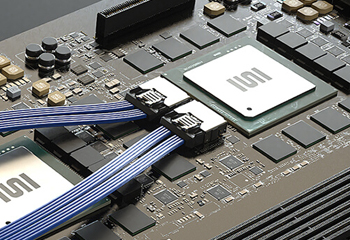

Optics

Optical cable assemblies were originally of interest to medical designers because they are non-magnetic. But they have become popular because of the data rates (obviously) and the connector’s miniature footprint. The FireFly™ optical cable system allows for greater density and closer proximity to the IC, enabling chip-to-chip, board-to-board, on-board, and system-to-system connectivity. The data rates achieved with optics allow designers to incorporate future functionality upgrades without having to redesign their boards.

Optical cable assemblies were originally of interest to medical designers because they are non-magnetic. But they have become popular because of the data rates (obviously) and the connector’s miniature footprint. The FireFly™ optical cable system allows for greater density and closer proximity to the IC, enabling chip-to-chip, board-to-board, on-board, and system-to-system connectivity. The data rates achieved with optics allow designers to incorporate future functionality upgrades without having to redesign their boards.

Further information

To the products

Your contact person

retour à "News"

The

The  High-speed cable assemblies

High-speed cable assemblies Optical cable assemblies were originally of interest to medical designers because they are non-magnetic. But they have become popular because of the data rates (obviously) and the connector’s miniature footprint. The

Optical cable assemblies were originally of interest to medical designers because they are non-magnetic. But they have become popular because of the data rates (obviously) and the connector’s miniature footprint. The